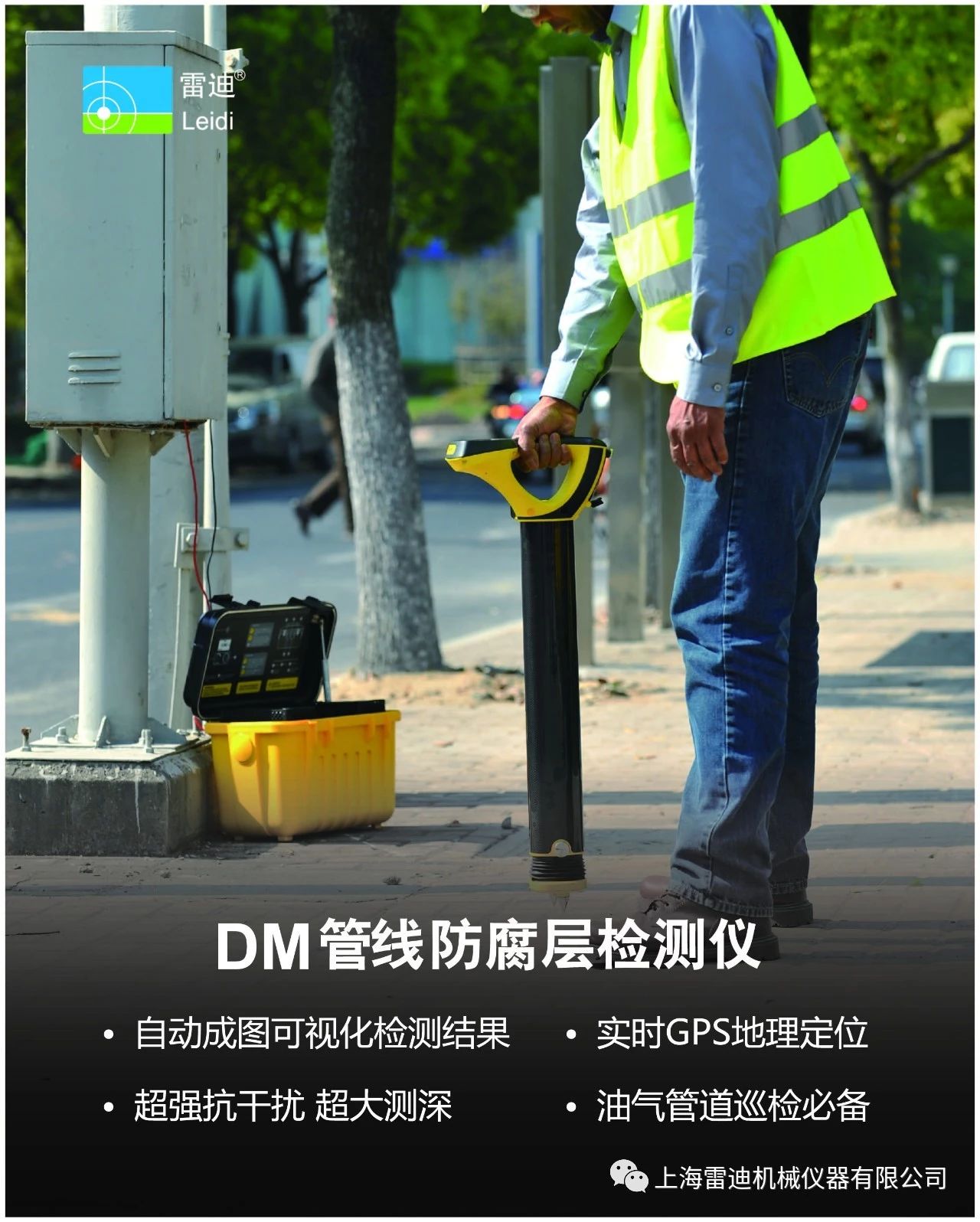

How to improve the detection of damaged points in oil pipelines

Product Details

Case Background

Case location: Nanning, Guangxi

Demonstration instruments: DM pipeline anti-corrosion layer detector, vLp2 pipeline detector

Detection Details

Detection process:

Firstly, connect the test pile on site. The distance of the oil pipeline to be explored is about 3 kilometers, and prepare thoroughly for the next step of exploration by properly grounding it.

Connect the black clip to a nearby iron piece that is driven underground, with low impedance. Adjust the output current of the transmitter to 2A, using a frequency of 3+6+128HZ. At the beginning of the detection, the pipeline is buried at a depth of about 2 meters, and gradually extends up the mountain, with a maximum depth of about 4 meters. Use a receiver in conjunction with an A-frame for detection. Insert it into the ground every 10 meters, and obvious arrow changes can be observed at the damaged anti-corrosion layer of the pipeline. At the same time, the DB value is relatively high here.

The location of the damaged points found on the mountain is relatively concentrated, all at the previous construction site. Afterwards, the detection was carried out from the reeds along the pipeline, with a depth of about 2 meters. Over a 2-kilometer journey, more than ten damaged points were found. Among them, there are 4 relatively large damage points that require focused maintenance in the later stage. The customer is very satisfied with the product's performance.

Detection results

1. When conducting external anti-corrosion layer detection on DM, the first step is to ground it. A larger current can achieve better results.

2. When DM detects high voltage lines, it will be affected by the interference of the high voltage lines. At this time, it can detect at a distance from the high voltage lines

3. The detection depth of DM should be consistent with the burial depth specified in the customer's drawings.

4. DM can detect the external anti-corrosion layer with high accuracy even when it cannot pass through the pipeline.

5. When detecting pipelines occupied by construction areas or buildings, it is necessary to shorten the spacing of the detection and insert the A-frame as densely as possible to avoid missing detection of damaged points.