Technical Scheme for Underground Pipeline Detection (II) - Pipeline Detector

(1) Detection principle of pipeline instrument

Metal pipelines generally have moderate to high magnetic strength (K value generally ranges from 100 × 4 π× SI to 1000 × 10-6 × 4 π× SI), and their resistivity is generally 0.23 × 10-4 Ω M to 0.89 × 10-4 Ω M, with good conductivity and magnetism. Underground pipelines are generally laid in shallow soil layers within 5 meters below the surface. The topsoil layer is generally non-magnetic, with a resistivity ranging from a few ohm meters to several tens of ohm meters. This shows that there are significant electrical and magnetic differences between underground pipelines and their surrounding media. Therefore, the underground pipeline detector made using the principle of electromagnetic induction can accurately determine the distribution of underground metal pipelines and has the necessary geophysical prerequisites for detection.

(2) Detection method

By applying an alternating electromagnetic field of a certain frequency and appropriate intensity to the target pipeline, a corresponding alternating current passes between the target pipeline and the earth. This alternating current generates an alternating electromagnetic field of the same frequency in the surrounding space, forming a secondary alternating electromagnetic field anomaly around the target pipeline. By detecting this anomaly with a receiving device, the position of the target pipeline can be determined, achieving the purpose of detecting underground pipelines. The detection methods are divided into active source and passive source methods, among which the active source method includes direct connection method, clamp method, and induction method.

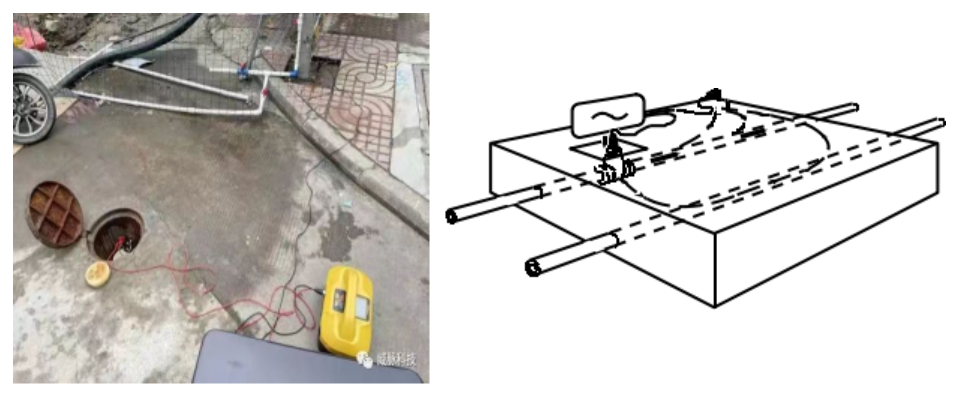

1. Direct connection method

Mainly utilizing exposed underground pipelines. For example, valves, manholes, various gauge boxes, etc. are used to detect metal pipelines. Method principle: One end of the transmitter is connected to the target pipeline under investigation, and the other end is grounded. The transmitter is used to directly apply the signal to the target pipeline, and the receiver is used to receive the signal and analyze its signal characteristics, which can determine the location of the underground pipeline. Mainly used for metal pipelines such as steel pipes, cast iron pipes, and metal wires.

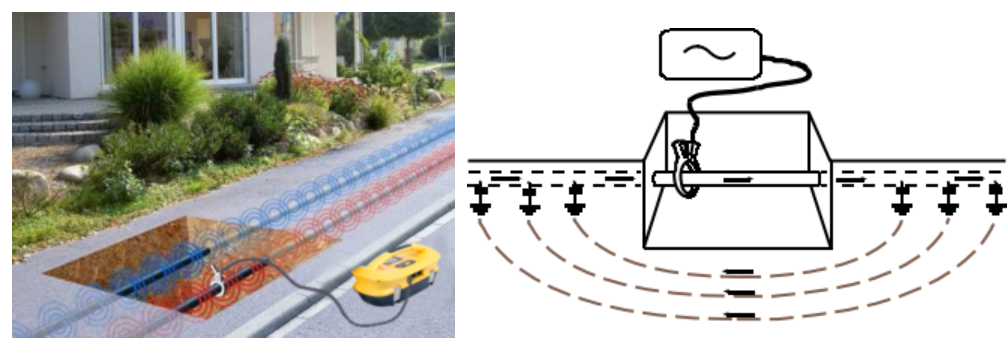

2. Induction method

According to the principle of electromagnetic induction, a transmitting coil with alternating current is placed above (or near) a metal pipeline. The coil generates an alternating electromagnetic field under the action of the alternating current and propagates it to the surrounding area. This electromagnetic field is called a "primary field". Due to the constantly changing magnitude and direction of the "primary field" magnetic flux passing through the metal pipeline, an induced current is generated in the metal pipeline, which is proportional to the rate of change of the magnetic flux and has the same frequency as the "primary field". Similarly, the induced current generates an induced electromagnetic field with the same frequency around it, known as the 'secondary field'. By receiving the "secondary field" signal at a certain distance through a receiving device, analyzing its distribution characteristics, the goal of finding underground metal pipelines can be achieved

3. Clamp method

The clamp equipped with a dedicated underground pipeline detector is used to clamp onto a metal pipeline. The signal is directly applied to the target pipeline through the induction coil on the clamp. The receiver receives the signal and analyzes its distribution characteristics to determine the location of the underground pipeline. It is mainly used for communication pipelines such as cables and optical cables.